Text and Images: William Blandford and Petter Olsson, Hydrotech-Veolia

The collaboration’s objective is to offer a new solution for aquaculture farmers who have particularly high demands for wastewater treatment. Bioretur’s sludge treatment plant processes and collects particulate sludge from land-based aquaculture facilities using traditional mechanical dewatering, achieving around 90% solids separation. However, for further removal of nitrogen and phosphorus, an additional polishing module is required to capture these nutrients even in dissolved form.

Demonstrating Water Treatment at Smolt Facility

Hydrotech-Veolia conducted a demonstration of the technology at one of Bioretur’s customer’s aquaculture facilities. The results exhibited a more substantial reduction in total suspended solids (TSS) and nutrients than anticipated.

Hydrotech’s Nutri-Pack chemically pre-treats the water before passing it through a drum filter. The water undergoes two stages: coagulation and polymer flocculation. This water treatment process has been used in wastewater treatment at municipal and industrial facilities for around 20 years. The new smart controller employs instruments to minimize chemical dosing. This has two advantages: it reduces chemical consumption and prevents the filter from clogging due to chemical transfer.

Efficient Polishing Module

The testing period covered a typical cycle for smolt growth. The quality of intake water varied over this cycle, with total suspended solids (TSS) concentrations increasing from 230 to 2467 mg-TSS/l, phosphorus from 5.3 to 29.4 mg-TP/l, and nitrogen from 11.0 to 50.9 mg-TN/l. This demonstrated the equipment’s performance under different conditions and provided vital insights into system sizing. It’s particularly important to know the size the filtration system needs to be and how often the system requires cleaning. The results are outlined in the fact box to the right.

Given the upcoming changes in limits for water discharge from land-based aquaculture facilities, this demonstration project provides insight into the value of modern wastewater technology.

Bioretur is confident that, in collaboration with Hydrotech and AnoxKaldnes, we can deliver an efficient polishing module that meets the future wastewater treatment requirements for land-based fish farming.

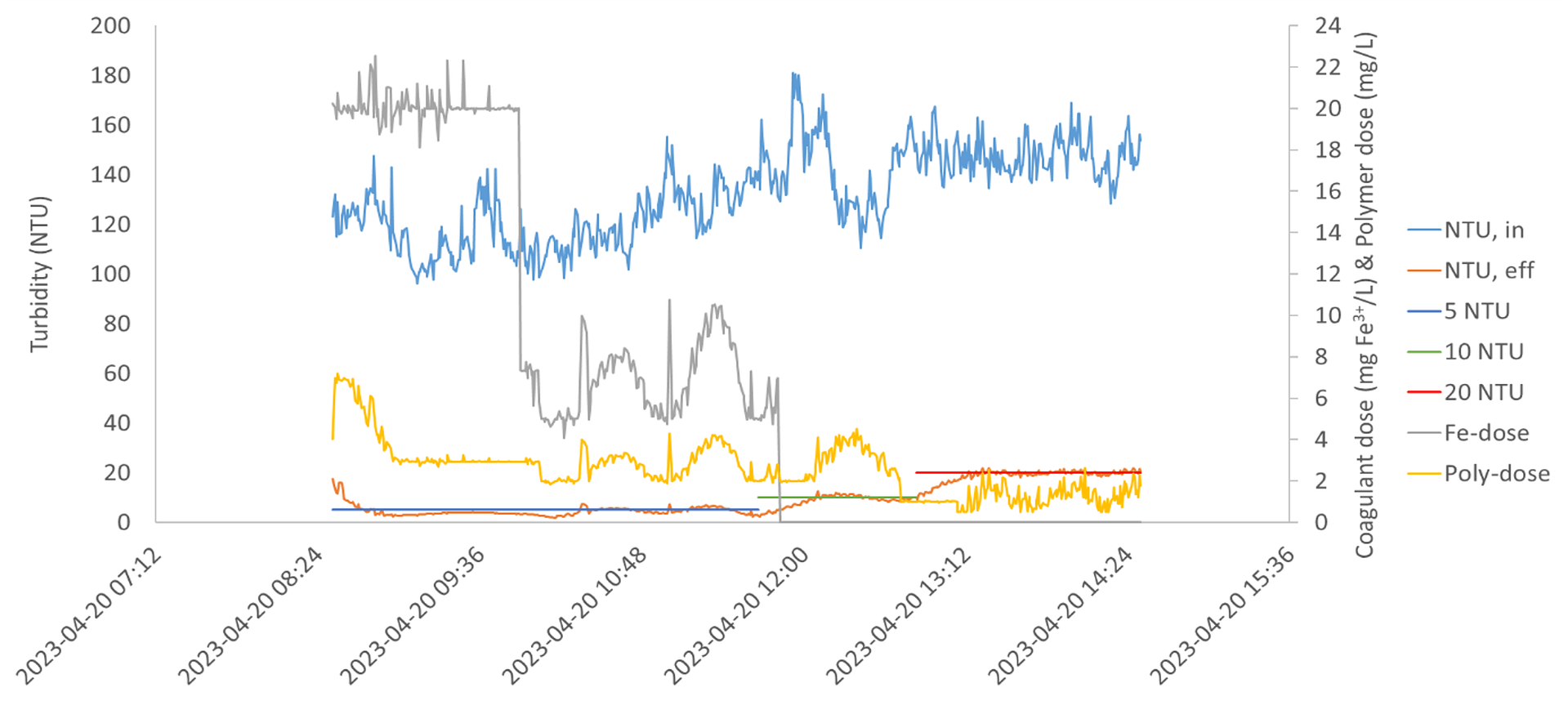

This graph simultaneously displays two things. The left side of the graph demonstrates the turbidity of the incoming water (“NTU, in”) and the clarity of the outgoing water (“NTU, eff”). The right side of the graph indicates the quantity of chemicals used for water treatment (“Fe-dose” for coagulant and “Poly-dose” for polymer). The lines on the graph depict the desired water clarity (standards of 5, 10, and 20 NTU).

Of particular interest is that the wastewater becomes significantly cleaner throughout the test, removing approximately 90% of the impurities (TSS). The green, blue, and red lines illustrate the desired water clarity. Hydrotech’s system can adjust the chemical dosing based on the incoming water’s level of impurity. The system is highly precise, reducing the likelihood of issues, thus minimizing the need for frequent operator adjustments.

More Information?

If you’re interested in learning more about the demonstration facility’s results, visit Hydrotech-Veolia at booth D-358.

Four presentations will be held:

• Wednesday, August 23rd – 11:00 AM and 3:00 PM

• Thursday, August 24th – 11:00 AM and 3:00 PM

Treatment Efficiency

Gjennomsnittlig reduksjonsytelse for demonstrasjonsanlegget:

Average reduction performance for the demonstration facility:

Total Suspended Solids: 98% Total Phosphorus: 97% Total Nitrogen: 56%*

* Laboratory tests have shown that the concentration of total nitrogen in water from this facility can be reduced by over 90% using a dedicated module provided by AnoxKaldnes (Hydrotech’s sister company).

This post is also available in: Norwegian Bokmål